BALLISTIC STANDARDS

The most common ballistic standards are UL 752 and the National Institute of Justice (NIJ)’s 0108.01. Both are summarized below in this article. Typically, UL 752 is the most common standard used because it is more modern, it is independently verified, it considers the penetration as well as injuries that could be caused by the spall from ballistic penetration and it’s more directly relevant to the construction industry. When ordering products, it’s important to specify the required level of ballistic protection.

The ratings for levels of bullet resistant glass are calculated by the protection the glass offers, based on the number of rounds fired before it breaks as well as the size of the weapon used. The projectiles fired by high-caliber, high-velocity weapons deliver the greatest amount of force to the target. This requires higher bullet resistant glass levels, which indicate a higher capacity for absorbing energy from the projectile. To be at the highest bullet proof glass levels, the entirety of the system — including the glazing material, frame and anchors — must be capable of absorbing the force from the projectiles. Simply having bullet proof glass installed in the framing system is not enough. The entire system must be rated highly enough to ensure the maximum level of protection. Our engineers design blast protection doors and windows that achieve the level of security your facility needs.

UL 752 Protection Standards for Bullet Resistant Glass

When you are looking at incorporating ballistic protection solutions, the most common standard in North America is UL 752. Developed by UL Solutions, formally Underwriters Laboratories, this standard provides a reliable framework for people to have the same expectations about products that offer ballistic protection, including glass. The test determines whether “protection is provided against complete penetration, passage of fragments of projectiles, or spalling (glass fragmentation) to the degree that injury would be caused to a person standing directly behind the bullet-resisting barrier.”

In addition, UL 752 standards also state “there shall be no opening of sufficient size to permit insertion of the muzzle of a standard weapon designed to use the ammunition used for the test completely through the glass”.

In layman’s terms, this means no part of the bullet or firearm can pass through the glass. Furthermore, it also means the person on the safe side of the glass won’t be sprayed with flying glass shards if the glass is shot.

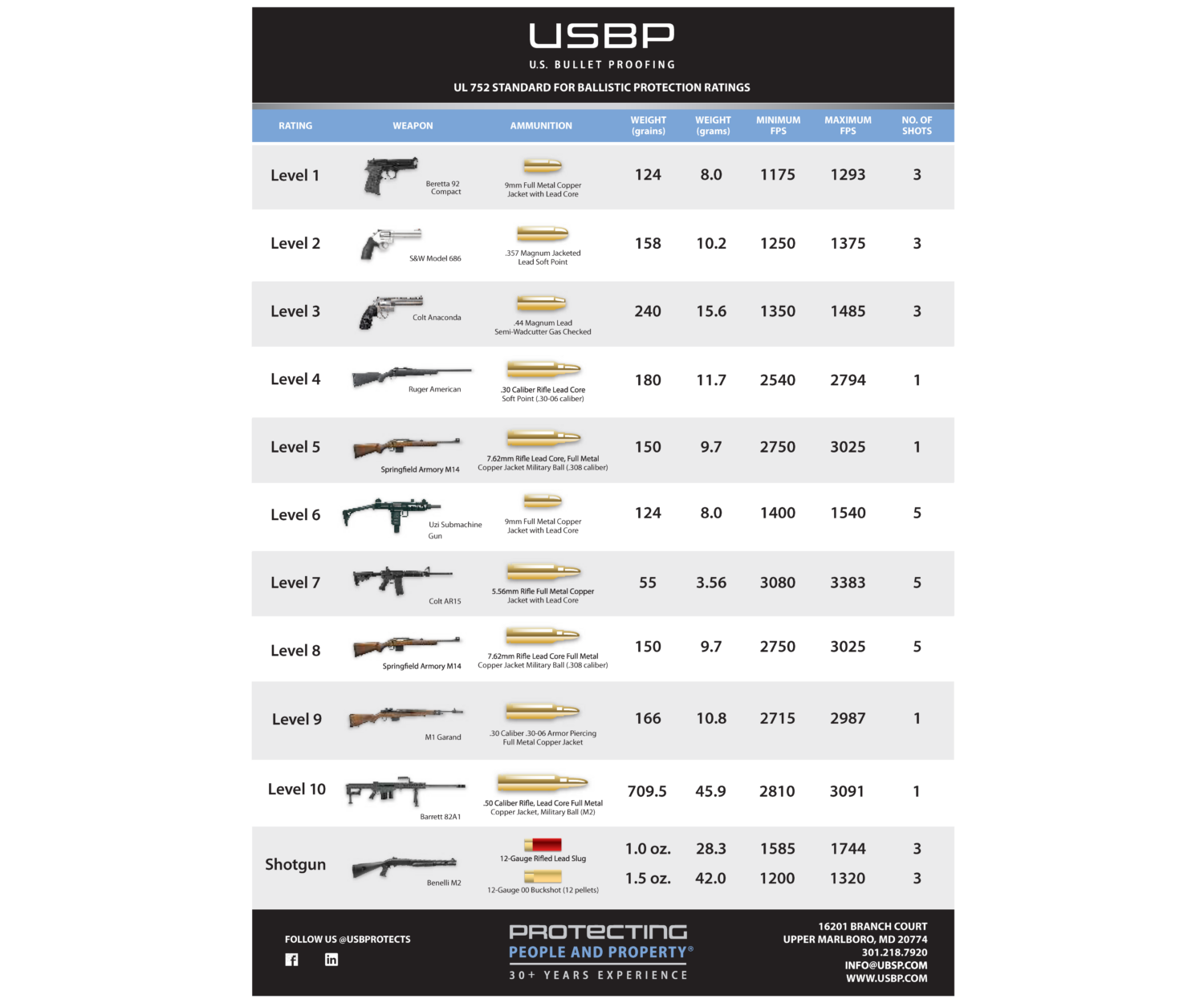

The level of the bullet resistance determines how much protection the glass will provide based on the firearm, ammunition, and the number of shots, although the levels are not necessarily linear. For example, Levels 1 and 6 are very similar. Both use a 124 grain 9mm Full Metal Copper Jacket with Lead Core. Level 1 has three shots; Level 6 uses five shots. The difference between Levels 1 and 6 are two extra shots.

Some of the most common applications we see include retail, financial, police stations, military, corrections facilities, churches and data centers. As you can imagine, a jewelry store has much different needs than an embassy. According to Statista, handguns were the most commonly used weapon in armed robberies in 2021 with 37,899 robberies. There are a few reasons why that is and many of them are probably obvious. Handguns are very popular, easily accessible and also easy to conceal.

Private businesses and homeowners looking for protection from armed robberies involving handguns, improvised weapons, knives/cutting instruments, and blunt objects benefit from the security provided from Levels 1 – 3 bullet-resistant glass. Level 3 is one of USBP’s best selling product since it covers all handgun levels and most high-threat applications.

Government agencies and armed forces require additional protection against conventional terrorist weapons including bombs, explosives, and small to medium size infantry automatic rifles. These national security-type projects typically use a combination of blast-resistant and UL 785 Levels 4 – 8 bullet-resistant glass.

What Type of BR Glass Is Best For Your Project?

Level 1 Rating: Provides protection from small caliber handguns up to 9mm and is often used for gas stations, transactions windows, retail/convenience stores, and pharmacies.

Level 2 Rating: Provides protection from large caliber handguns up to .357 magnum and is commonly used in financial institution such as banks, credit unions, and check cashing businesses.

Level 3 Rating: Provides protection from large bore, large caliber handguns up to .44 magnum and is frequently specified in high-risk and high-occupancy public buildings, including school and government facilities as well as law enforcement, courthouse, and prisons.

Levels 4 – 8 Ratings: Provides protection against automatic weapons, assault rifles, and large caliber rifles. Levels 4 – 8 are normally only used in embassies, government facilities, and military applications.

See the following chart for a more detailed breakdown of UL 752 Levels 1 through 8. Once you have determined the level of protection suitable for your application, you can start determining the correct complete solution for your building design.

A proper threat and risk assessment would help determine exactly what level of protection your organization needs. Consulting with our team early in a project can save time, money, and ensure the glass, walls, and frames in your facility matches the security requirements necessary to protect it.

NIJ Standard 0108.01

The NIJ 0108.01 is a very common ballistic resistance performance standard established by the National Institute of Justice (NIJ). It is a less common standard, but still provides a valid means to classify the level of ballistic protection required for the means of construction products.

NIJ Standard 0108.01 Ballistic Resistant Protective Materials

| ARMOR TYPE | TEST AMMUNITION | RQD. HITS PER SPECIMEN |

|---|---|---|

| I | LRHW Lead 38 Special RN Lead | 5 5 |

| II-A | 357 Magnum JSP 9mm FMJ | 5 5 |

| II | 357 Magnum JSP (higher velocity round) 9mm FMJ (higher velocity round) | 5 5 |

| III-A | 44 Magnum, LeadSWC Gas Checked 9mm FMJ | 5 5 |

| III | 7.62mm, 308Winchester FMJ | 5 |

| IV | 30-06 AP | 1 |

AP – Armor Piercing

LRHV – Long Rifle High Velocity

FMJ – Fu MetalJacket

RN – Round Nose

JSP – Jacketed Soft Point

SWC – Semi-Wadcutter

BALLISTIC GLASS WINDOWS AND DOORS

U.S. Bullet Proofing understands the importance of protecting people and property, which is why we’re committed to engineering, manufacturing and installing the best ballistic glass windows in the industry. These feature multiple layers of glass in varying thicknesses. The higher the number of layers and the thicker the glass, the better they are at stopping bullets and other ballistic threats. Ballistic glass windows that incorporate laminated glass sometimes use special polycarbonates, which are the most protective glazing available.

Contrary to popular belief, bullets don’t bounce off ballistic glass windows. The multiple layers of reinforced glass gradually erode the penetration speed of the bullet, absorbing its kinetic energy and slowing it down enough that it doesn’t fully penetrate the window.

For maximum safety, the designer and end user of these solutions must understand how suitable the product is for the specific application. When it comes to protective design and security, architects and engineers are responsible for equipping the facilities they create with the most appropriate level of protection based on the threats they are most likely to face.

U.S. Bulletproofing is a pioneer in the design and supply of aluminum window and door systems that provide high-level protection from ballistics, blast, storm impact and forced entry. Our job is Protecting People and Property®, and we take that responsibility very seriously as evident in quality of products we provide and the scale and the iconic type of projects that have incorporated our solutions. Contact one of our sales representatives today to learn more about how we can help you with your next security project.