How Bullet Resistant Glass Really Works

Over the years, there has been a demonstrable increase in the power of handheld firearms, as well as their accessibility. In response, bullet resistant technology also has come a long way. As guns have become more powerful and more readily available, protecting your property and the people inside it has become more imperative.

One of the best steps you can take to secure your building is to install bullet resistant glass. There’s a reason why high-risk properties — from embassies to banks to schools — have come to rely on windows and doors made from these materials to secure and protect them. As a leader in the design, engineering and creation of these high-security products, U.S. Bullet Proofing is proud to supply them to customers around the world who value keeping their properties safe. How does bullet proof glass work? Read on to learn the answer as well as why the term “bullet proof” is a bit of a misnomer.

How Bullet Proof Glass Works

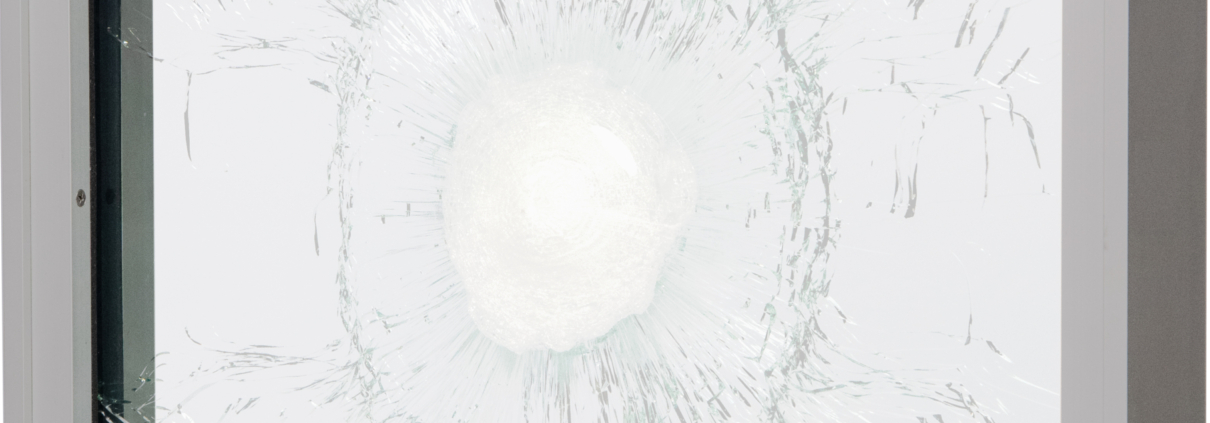

Although the term “bullet proof” is used frequently to describe windows and doors made with bullet resistant glass, the truth is that the protection they offer is more complicated. A modern bullet can travel at speeds of up to 1,800 miles per hour after it leaves the barrel of a gun. Even though a single bullet is very small, the amount of concentrated energy it can transfer to a target is extremely powerful. Repeated impacts with such force can wear down even the hardest materials over time, especially when talking about something as inherently rigid as glass.

Bullet resistant glass, however, is designed and manufactured to offer a greater level of protection than standard windows or doors can provide. The key is in how the glass reacts to the force exerted by a bullet.

Absorbing Energy

Standard glass is not known for its elasticity. Generally, it takes relatively little force to cause it to break instead of bending the way metals, wood and plastics can. A bullet exerts enough force to instantly shatter regular glass, so what makes bullet resistant glass different? The secret is not in changing the properties of the glass, but in supporting it with other materials that will absorb the energy of the bullet before it can be transferred to the glass.

One of the most common methods of how bullet resistant glass is made involves laminating layers of polycarbonate plastic between panes of glass. This means that a bullet may break through the first layer of glass, but the plastic’s elastic nature absorbs much of the force of the bullet without breaking. The bullet continues to travel, but without a significant portion of its original speed and energy. It will break through the next layer of glass, but the second layer of plastic will absorb even more of its kinetic energy. The result is that the bullet is robbed of so much energy that it cannot fully penetrate the window or door.

Another common method of creating bullet resistant glass is to use acrylic glazing, which is also known as plexiglass. This material is just as transparent as regular glass but is entirely made of plastic. Depending on the level of protection desired, panes can be one to two inches thick, ensuring that it has enough elasticity to dampen the force of any bullets that impact the surface. In the case of smaller-caliber ballistics, plexiglass may even be enough to repel projectiles, rather than simply slowing them.

Choose U.S. Bullet Proofing to Protect People and Property

Although no protection method is 100% effective against all threats, bullet-resistant windows and doors from U.S. Bullet Proofing offer you exceptionally high levels of security. Our in-house engineering capabilities enable us to develop and manufacture products that will meet your needs. Our products are built to withstand the highest levels of ballistic protection levels. We have developed our products to complement today’s architectural doors and windows so they will fit seamlessly into your building’s design and aesthetics.

Since 1988, we have developed a strong reputation for creating the best security products available. Everything we make has been developed with pride and an exceptional attention to detail that make our offerings the industry standard. If you want to learn more about what we have to offer, reach out and get in touch with us today.