What Is Spalling In Ballistic Glass And Why Is It Important?

Protecting your property and the people within means knowing as much about what you use to defend them as possible. Although bullet-resistant glazing offers a much higher degree of protection from ballistics and other threats than standard windows or doors, it is not perfect nor invincible. There are many other considerations and levels of resistance, and it’s critical to know what to expect from them before you start planning your project.

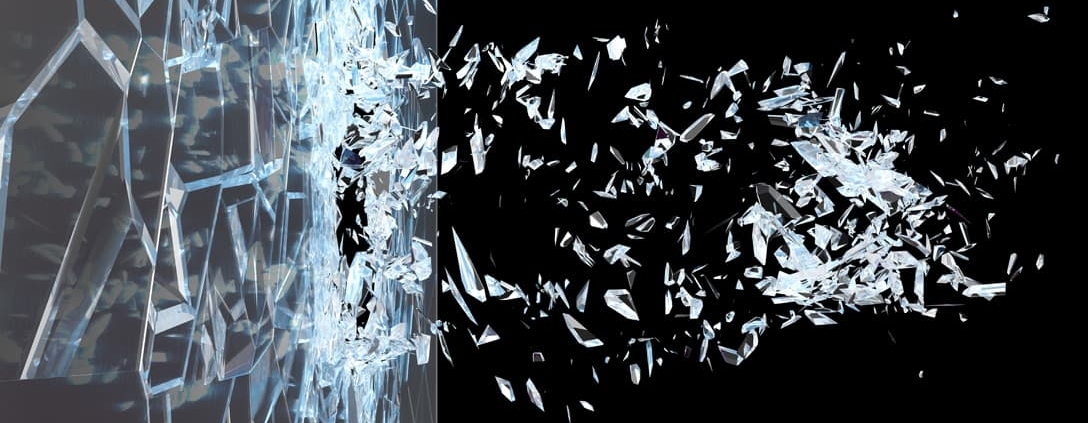

For example, when ballistic glazing is struck by a bullet, spalling can occur. Spalling refers to the fragments of glazing that can be ejected from the panels after being struck by a high-velocity projectile. This can have a significant impact on how you choose the products you use to secure your building. Even though ballistic glazing may prevent a bullet from penetrating the window or door and striking someone inside the building through the glass, spalling on the inside may still strike the occupants and potentially cause injuries.

How Materials Influence the Severity of Spalling

The amount of spalling that occurs when a bullet-resistant panel is struck depends a lot on the materials used in its construction and how they are assembled. One of the most commonly used types of glazing is glazing-clad polycarbonate, which is created by sandwiching multiple layers of glazing and polycarbonate together using a special laminate between each. As a bullet impacts the glazing, its energy is absorbed by each layer. This reduces its speed and force before it can penetrate all the way through. In essence, this type of glazing “catches” the projectile.

However, there still may be enough force generated by the bullet to shatter the outermost layer of the glazing and send it flying inside the building. This means that although the threat posed by the bullet itself may be mitigated, there still remains a certain amount of risk to those on the other side of the glazing. It is important to note that UL 752 Standard for Bullet-Resisting materials allows for a certain amount of spalling in ballistic glazing. The standard specifies that any spall emitted by a product must not be capable of causing injury to a person standing at least 18 inches away from the secure side of the glazing.

Although many types of bullet-resistant glazing produce spalling, there are some products that offer additional protection. Low-spall options typically utilize forms of tempered glazing that don’t shatter as easily, reducing the risk and severity of any spalling that may occur. For maximum protection, however, there are no-spall panels that feature an additional sheet of polycarbonate on the secure side of the glazing. This effectively contains any spalling that might have been released from the panels.

Choosing the Right Option for Your Needs

As you determine which type of bullet-resistant glazing you need for your property, it’s important to think about the possible effects of spalling and whether it makes sense for you to mitigate it. Although low- and no-spall glazing offers the advantage of protecting your building from spall, it comes with some caveats. For example, the additional sheet of polycarbonate over the glazing is softer and can be scratched much more easily than the other materials. It also can be damaged by cleaning products that contain ammonia, meaning you need to be exceptionally careful with it. Even a common household glazing cleaner can be harmful to this type of glazing, causing a chemical attack and a process called ‘crazing’ which appear like large defective cracks in the glazing.

The experts at U.S. Bullet Proofing are well-versed in all the ballistic standards and what they mean for you. When you work with us to protect your property and the assets within, you have the expertise to select the materials and level of protection that makes the most sense for your needs. Get in touch with us today to learn more about how we can help you.